Laser quality, or measurement precision, is a function of the laser power, focusing optics, part surface roughness, surface reflectivity and the amount of error introduced by external factors such as temperature fluctuations and vibration. "Alignment accessories allow for the scanning system to make sure it has aligned the laser scanner to the coordinate system orientation of the scanning system or part coordinate space." Part referencing accessories allow object scanning from different orientations of the scanner to the part to be merged together into the same coordinate system easily, or in some cases automatically.

Martin Schuster, president of Laser Design Inc. "System and laser calibration accessories make automated calibration confirmation easy and fast to ensure the laser probe itself is operating within tolerance," says C. To further ensure quality, most laser measurement devices have accessories performing calibration checks, alignment checks or part referencing of scan data. According to Cris Holmes, machine vision and sensor product manager at Axis Systems (Auburn Hills, MI), what makes a laser high end is primarily how the data is handled because inexpensive controllers can be configured to look for a set point match for a specific measurement. There are inexpensive, low-end and more complex high-end laser measurement devices. The closer the laser is to the object, the higher percentage of light will be returned.Ī laser measurement system enables measurements via walk-around scanning without mechanical constraints. The laser sensor receiver can use the percentage of laser light reflected off the test object surface to determine the distance from the laser. Single-point lasers project the laser beam onto a single point on the target and then return data. Single-point lasers with spot beams as small as 50 microns can be used on very small objects or features to confirm their presence.

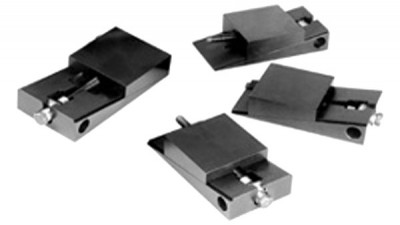

Other types of laser-beam configurations allow for the checking of surface flatness, porosity, diameters, gaps, positioning, velocity, eccentricity, surface inclination, thickness and height. According to Glenn Valliant, managing partner of Optical Dimensions (Lake Forest, CA), at the low end, there are simple laser sighting and surveying measurements that take advantage of the ‘straightness' of light. Laser systems range from single-axis measurers to large 3-D point cloud devices. Selecting the correct laser system best ensures quality. A laser surface measurement head in a fixture measures valve caps.

0 kommentar(er)

0 kommentar(er)